Up-Down Turning Roller Table for Ceramic Tiles Glazed Line

The ceramic tile industry is constantly evolving, with innovative machinery playing a pivotal role in enhancing the efficiency and quality of production. Among the critical components in the glazed line of ceramic tile production is the Up-Down Turning Roller Table. Designed to facilitate the smooth and efficient movement of tiles between different levels of the production process, this equipment is a vital element for modern manufacturing setups. This article delves into the features, advantages, and applications of up-down turning roller tables in the ceramic tile industry.

Understanding the Up-Down Turning Roller Table

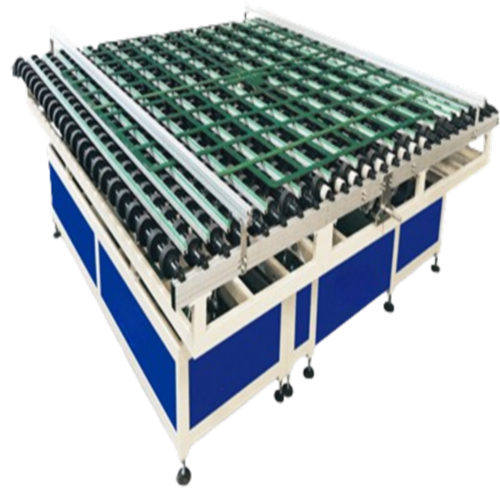

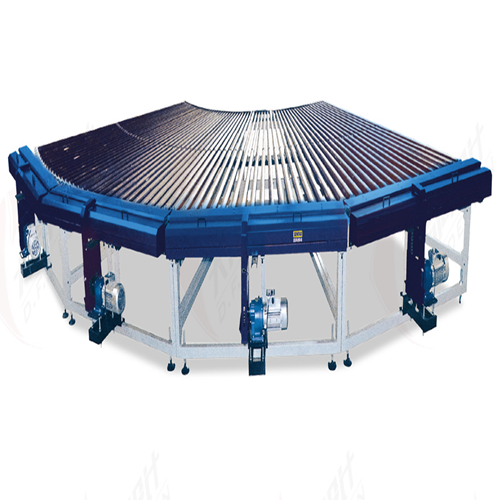

The Up-Down Turning Roller Table is an advanced conveyor mechanism engineered to transfer ceramic tiles seamlessly between varying heights in a production line. This feature is particularly important in complex glazing lines where tiles need to move between different levels for processes such as glazing, drying, and inspection.

Equipped with precision rollers and robust frameworks, these tables ensure that tiles are transported smoothly and securely, maintaining their integrity throughout the process. They are especially beneficial for handling large and heavy tiles that require careful management to avoid damage.

Features of Up-Down Turning Roller Tables

Height Adjustment Mechanism: The table is equipped with a reliable system for adjusting the height to meet specific production requirements. This ensures flexibility and adaptability in complex layouts.

Heavy-Duty Rollers: Designed with high-grade materials, the rollers can withstand the weight and pressure of large ceramic tiles, ensuring smooth and steady movement.

Smooth Transition Design: The up-down turning mechanism facilitates seamless transitions, reducing the risk of tile breakage or misalignment.

Modular Structure: A modular design allows easy integration into existing production lines, making it versatile and scalable for various manufacturing setups.

Energy-Efficient Operation: Advanced models feature energy-efficient motors and systems to minimize power consumption while maintaining high performance.

Safety Features: Safety guards and anti-slip systems are incorporated to protect both the tiles and the machinery during operation.

Benefits of Up-Down Turning Roller Tables

1. Streamlined Production Process

By efficiently moving tiles between different levels, these roller tables eliminate manual handling, saving time and reducing labor costs.

2. Enhanced Tile Safety

The smooth and controlled movement minimizes the risk of breakage or damage, ensuring high-quality output.

3. Adaptability

The height-adjustable design allows manufacturers to customize the equipment according to their specific needs, enhancing overall flexibility.

4. Durability and Longevity

Constructed with high-quality materials, these roller tables are built to last, even in demanding production environments.

5. Cost Efficiency

Reduced maintenance needs and minimized tile wastage contribute to lower operational costs, making it a cost-effective solution for manufacturers.

Applications in the Ceramic Tile Glazed Line

1. Level Transitions

The primary application of up-down turning roller tables is to facilitate the movement of tiles between different levels in the production line, such as from the glazing station to the drying unit.

2. Integration with Automation

These tables can be integrated with automated systems like robotic arms and conveyor networks, streamlining the entire production process.

3. Handling Large and Heavy Tiles

Large-format tiles are particularly challenging to handle, but the robust design of up-down turning roller tables makes them ideal for this application.

Future Trends in Roller Table Technology

The future of up-down turning roller tables lies in further advancements in automation and sustainability. Key trends include:

IoT Integration: Smart sensors and monitoring systems for real-time performance tracking.

Energy Efficiency: Development of low-energy motors and systems to reduce environmental impact.

Advanced Materials: Use of lightweight yet durable materials for enhanced performance.

Customization: Increased focus on tailor-made solutions to meet specific industry needs.

To summarize:

The Up-Down Turning Roller Table is a game-changer in the ceramic tile manufacturing industry. Its ability to facilitate smooth and efficient movement of tiles between different levels ensures high productivity, superior quality, and reduced operational challenges.

At Aexea International, we are proud to offer cutting-edge solutions tailored to the needs of the ceramic tile industry. Our up-down turning roller tables are designed with precision and durability to help manufacturers achieve their production goals. Partner with us for innovative and reliable equipment that takes your production process to the next level.