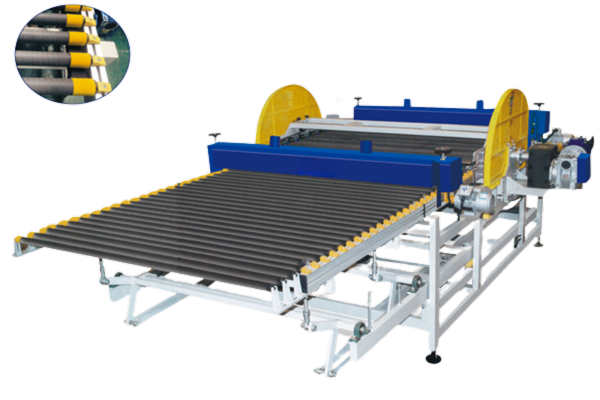

LARGE-SIZED CURVE ROLLER TABLE

The Large-Sized Curve Roller Table is an indispensable component of the ceramic tile glazed line, especially in the production of large-format tiles.

Benefits of Large-Sized Curve Roller Tables

Enhanced Efficiency

Minimized Tile Breakage

Reduced Operational Costs

SEVEN-LAYER ROLLER TABLE

Specialized piece of equipment designed to streamline operations in the glazed line

UP-DOWN TURNING ROLLER TABLE

The Up-Down Turning Roller Table is a game-changer in the ceramic tile manufacturing industry.

State-of-the-art Equipment

GLAZE LINE TURNOVER MACHINE

A glaze line turnover machine is an advanced piece of equipment designed to handle ceramic tiles during the glazing process.

GLAZE LINE ROTATING TURING MACHINE

This state-of-the-art machine is specifically designed to optimize the glazing process by ensuring seamless tile rotation and alignment during production.

BISCUIT BRUSH MACHINE

The biscuit brush machine is a cornerstone of excellence in ceramic tile manufacturing. By ensuring clean and defect-free tile surfaces

What our clients say

How they are feel from our products & service? Hear from our newest members.

The team’s professionalism and support throughout the process have been exceptional. We highly recommend Aexea International for anyone looking to elevate their manufacturing capabilities and efficiency with preciseness.

Supera Granito LLP Mr. Deep Gami

Aexea International has exceeded our expectations with their Ceramic Tile Glazed Line equipment. The quality, durability, and performance of their machines have significantly improved our production efficiency

Livolla Granito LLP Mr. Shailesh

Aexea International provided high-quality ceramic tile machinery that improved our production efficiency. Their expert guidance, prompt support, and professional service made our purchase experience smooth, reliable, and satisfying.

Somani Max Pvt Ltd Niravbhai

Aexea International delivered excellent ceramic tile plant machinery. Their professional guidance, timely support, and smooth installation improved our production efficiency, making them a reliable and valuable partner today.

Spentagon Ceramic Pvt Ltd Pintubhai Baraiya

“Aexea International supplied outstanding ceramic tile plant machinery. Their technical guidance, prompt support, and smooth installation greatly improved our production efficiency. A reliable partner delivering quality solutions and excellent service.”

Lorison Tiles LLP Suraj Padsubiya

“Aexea International provided excellent ceramic tile plant machinery with reliable performance. Their expert guidance, timely support, and smooth installation improved our production efficiency. A trustworthy partner delivering quality and professionalism.”

Aarko Granito LLP Hiteshbhai

“Aexea International delivered high-quality ceramic tile plant machinery. Their expert support, smooth installation, and professional service boosted our production efficiency. We trust Aexea for solutions and great success for our production line.”

Taurus Tiles Pvt Ltd Jigarbhai“Sourcing the Best, Delivering the Finest – Aexea International Leads the Way.”

Watch our gallery

FINISHED BRICK TURNING MACHINE

COMPENSATOR

Intelligent buffer system that manages tile flow seamlessly

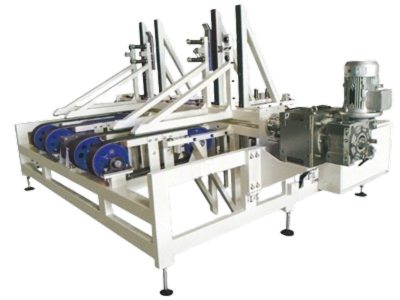

COMMON COMPENSATOR

A Common Compensator is a machine designed to balance and regulate the flow of ceramic tiles on a production line, particularly in glazing processes. It ensures that tiles are uniformly spaced and aligned while compensating for variations in production speeds, line stoppages, or downstream bottlenecks. By maintaining consistent material handling, the Common Compensator optimizes the efficiency and reliability of the entire production line.

The Common Compensator represents a critical advancement in ceramic tile production, addressing the challenges of efficiency, precision, and material handling. By ensuring consistent tile flow and alignment, the machine optimizes glazing processes and enhances overall production quality.

Aexea International’s commitment to innovation and excellence is evident in its development of the Common Compensator. With customized solutions, expert support, and a focus on sustainability, Aexea continues to set new standards in the ceramic tile manufacturing industry. As the industry evolves, the Common Compensator will remain an indispensable tool for manufacturers seeking to achieve excellence in their production lines.

Working with Aexea International has been a game-changer for our production line. Their Ceramic Tile Glazed Line solutions are not only cutting-edge but also incredibly reliable, helping us achieve unmatched precision and efficiency

Quro Granito LLP Mr. Navneet Jivani