Seven-Layer Roller Table: A Key Innovation in Ceramic Tiles Glazed Line for Aexea International

In the competitive world of ceramic tile manufacturing, innovation and efficiency are critical for maintaining market leadership. Aexea International, a renowned name in the ceramics industry, has consistently invested in advanced technologies to enhance its production processes. Among its key innovations is the seven-layer roller table, a specialized piece of equipment designed to streamline operations in the glazed line of ceramic tile production.

This article provides an in-depth analysis of the seven-layer roller table, exploring its structure, functionality, benefits, and significance in the ceramic tile manufacturing process.

Overview of the Seven-Layer Roller Table

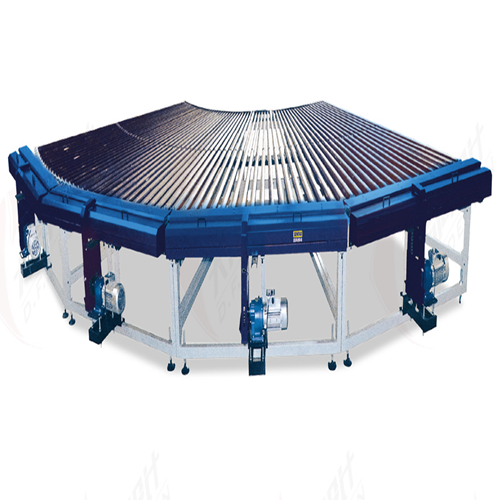

The seven-layer roller table is a high-capacity material handling system used primarily in the glazing lines of ceramic tile production. Its multi-layered design allows for efficient storage, transport, and staging of tiles during various production phases. The roller table not only optimizes space utilization but also ensures smooth and consistent movement of tiles through the glazing process.

Functionality of the Seven-Layer Roller Table

The seven-layer roller table operates through a combination of mechanical and automated processes, ensuring efficient handling of tiles during the glazing process. Below is a step-by-step outline of its functionality:

Tile Loading

Tiles are loaded onto the roller table, either manually or through automated loading systems. Each tile is directed to a specific layer based on production requirements.Layer Allocation

The control system allocates tiles to different layers of the table, optimizing space and ensuring a balanced distribution of weight.Horizontal and Vertical Movement

The rollers facilitate the horizontal movement of tiles along each layer, while the lifting mechanism enables vertical transfer between layers.Staging and Transport

The table serves as a staging area where tiles are temporarily stored before moving to the next stage of the production line, such as glazing, drying, or firing.Tile Unloading

Once the tiles are ready for the next process, they are unloaded from the roller table and transferred to the subsequent production stage.

Advantages of the Seven-Layer Roller Table

The adoption of a seven-layer roller table offers numerous benefits to ceramic tile manufacturers, particularly in the glazing line:

Space Optimization

The multi-layer structure maximizes vertical space utilization, reducing the need for expansive factory layouts.Increased Production Efficiency

By enabling simultaneous handling of tiles on multiple layers, the roller table increases the throughput of the production line.Reduced Handling Damage

Automated and precise movement of tiles minimizes the risk of chipping, cracking, or other forms of damage during handling.Enhanced Workflow Management

The roller table serves as an effective buffer system, accommodating production variations and ensuring a smooth workflow.Time Savings

The efficient transfer and staging of tiles significantly reduce idle time between production stages.Scalability

The table’s design can be customized to accommodate different tile sizes, weights, and production volumes.Improved Operator Safety

Automation and safety features reduce the need for manual handling, lowering the risk of workplace injuries.

Aexea International’s Implementation

As a leader in ceramic tile manufacturing, Aexea International has integrated the seven-layer roller table into its glazed line processes, achieving remarkable results. The company’s implementation strategy includes:

Customization for Diverse Tile Types

Aexea International has tailored its roller tables to handle a wide range of tile sizes and designs, catering to varied customer demands.Integration with Automated Systems

The roller tables are seamlessly integrated with Aexea’s automated glazing lines, ensuring synchronized operations and data-driven decision-making.Focus on Sustainability

By optimizing space and reducing material wastage, the roller tables align with Aexea’s commitment to sustainable manufacturing practices.Continuous Improvement

Aexea invests in regular maintenance and upgrades of its roller tables to maintain peak performance and incorporate the latest technological advancements.

To summarize:

The seven-layer roller table represents a significant leap in ceramic tile manufacturing technology, particularly in the glazing process. Its ability to optimize space, enhance efficiency, and improve product handling makes it an invaluable asset for manufacturers like Aexea International. As the industry continues to evolve, the roller table will undoubtedly play a central role in shaping the future of ceramic tile production.

By embracing this innovative technology, Aexea International reinforces its position as a pioneer in the ceramics industry, delivering superior products while maintaining operational excellence.