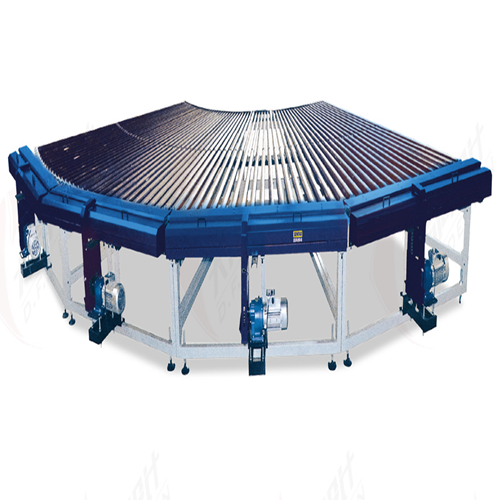

Large-Sized Curve Roller Table for Ceramic Tiles Glazed Line

The ceramic tile industry has seen tremendous advancements over the years, with innovation driving efficiency, durability, and quality in manufacturing processes. One such essential component in the production of ceramic tiles is the Large-Sized Curve Roller Table, a vital element of the ceramic tile glazed line. This equipment is specifically designed to facilitate the seamless movement and processing of tiles during glazing, ensuring superior quality and precision. This article delves into the significance, features, benefits, and applications of large-sized curve roller tables in the ceramic tile manufacturing process.

Features of Large-Sized Curve Roller Tables

Heavy-Duty Construction: Large-sized curve roller tables are built with heavy-duty materials such as stainless steel or high-grade aluminum to withstand the weight and pressure of large ceramic tiles. These materials ensure longevity and resistance to wear and tear.

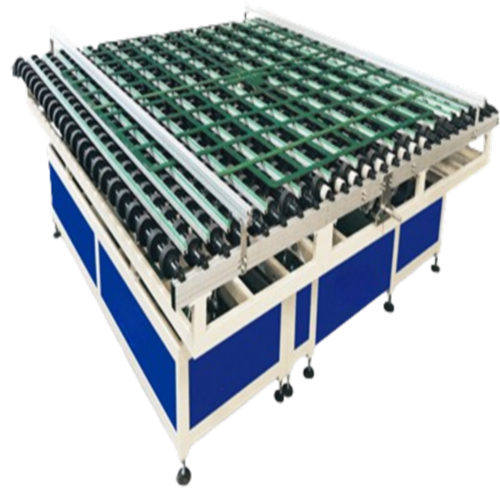

Precision Rollers: The rollers are designed with high precision to reduce friction and ensure smooth movement of tiles. Some models include rubber-coated rollers to provide extra grip and minimize slippage.

Adjustable Angles: These tables can be customized to fit specific curve angles required in the production line. Whether it’s a 45-degree or 90-degree curve, the table can be tailored to meet production needs.

Modular Design: A modular design allows easy integration into existing glazing lines. The table can be expanded or reconfigured as needed, making it versatile for different production setups.

Shock Absorption Technology: Advanced models feature shock-absorbing systems to handle the impact of heavy tiles, ensuring smooth transitions without damaging the tiles.

Speed Control: Equipped with variable speed settings, the table allows operators to adjust the roller speed to match the overall pace of the production line.

Benefits of Large-Sized Curve Roller Tables

1. Enhanced Efficiency

Curve roller tables streamline the production process by enabling tiles to navigate curves seamlessly. This reduces the need for manual intervention, saving time and labor costs.

2. Minimized Tile Breakage

Large-sized tiles are more prone to breakage due to their size and weight. The smooth and steady movement provided by the curve roller table minimizes stress on the tiles, reducing the likelihood of damage.

3. Customizable Solutions

These tables can be tailored to suit specific production line requirements, whether it involves handling unique tile sizes, curve angles, or load capacities.

4. Durability and Longevity

The use of high-quality materials and robust engineering ensures that curve roller tables can withstand the demands of a high-production environment for extended periods.

5. Improved Quality Control

By ensuring uniform movement and minimal interruptions, curve roller tables contribute to consistent tile quality, reducing defects and ensuring that finished products meet industry standards.

6. Reduced Operational Costs

With less manual intervention, lower maintenance needs, and minimized tile breakage, curve roller tables help manufacturers cut down on overall operational expenses.

Future Trends in Curve Roller Table Technology

As the ceramic tile industry continues to evolve, so does the technology behind curve roller tables. Here are some emerging trends:

Smart Automation: Integration with IoT-enabled systems for real-time monitoring and control.

Energy Efficiency: Development of energy-efficient roller systems to reduce environmental impact.

Advanced Materials: Use of lightweight, durable materials to improve performance and reduce wear and tear.

Enhanced Customization: Greater flexibility in design to cater to unique production requirements.

To summarize:

The Large-Sized Curve Roller Table is an indispensable component of the ceramic tile glazed line, especially in the production of large-format tiles. Its ability to facilitate smooth, efficient, and reliable tile movement ensures high-quality output while minimizing operational challenges. For manufacturers seeking to enhance productivity, reduce costs, and maintain the highest standards of quality, investing in a well-designed curve roller table is essential.

At Aexea International, we specialize in providing state-of-the-art solutions for the ceramic tile industry, including high-performance large-sized curve roller tables. With our commitment to innovation and customer satisfaction, we are proud to support manufacturers in achieving their production goals. Let us help you take your ceramic tile production to the next level with cutting-edge equipment designed for excellence.