Kiln Exit Turnover Machine for Ceramic Tiles Glazed Line

Introduction

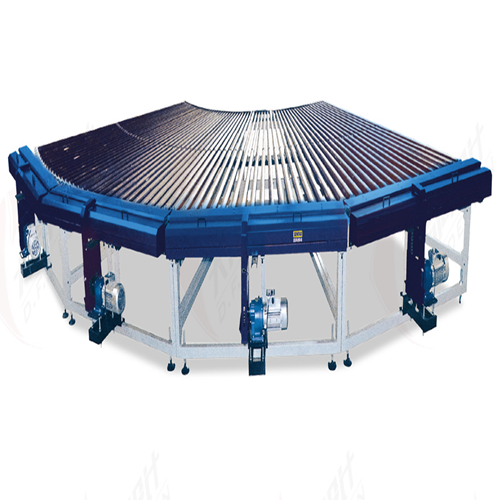

The ceramic tile industry relies heavily on automation to ensure efficiency, precision, and quality. One of the critical pieces of equipment in a ceramic tile production line is the Kiln Exit Turnover Machine. Positioned at the kiln exit, this machine plays a vital role in flipping, cooling, and aligning ceramic tiles before they proceed to further processes such as glazing and sorting.

Aexea International is a trusted supplier of high-quality Kiln Exit Turnover Machines, offering innovative solutions that improve manufacturing efficiency, reduce tile breakage, and enhance product consistency. This article explores the functionality, benefits, features, and selection criteria of kiln exit turnover machines, emphasizing Aexea International’s industry-leading solutions.

Understanding the Kiln Exit Turnover Machine

A Kiln Exit Turnover Machine is designed to handle hot tiles exiting the kiln. This machine carefully flips and repositions the tiles to ensure proper cooling and smooth transition to subsequent production stages. Without proper flipping, tiles can suffer from thermal stress, warping, or misalignment, leading to defects and production inefficiencies.

Key Functions of the Kiln Exit Turnover Machine

- Tile Flipping: Ensures uniform cooling and minimizes thermal stress.

- Precision Alignment: Positions tiles correctly for glazing or sorting.

- Damage Prevention: Uses controlled flipping mechanisms to prevent breakage.

- Automated Sorting: Works with conveyors to streamline tile handling.

- Speed Synchronization: Matches kiln output speed for smooth production flow.

Features of a High-Quality Kiln Exit Turnover Machine

1. Robust and Heat-Resistant Construction

- Made from high-temperature resistant materials to withstand exposure to freshly fired tiles.

- Reinforced components for long-lasting durability.

2. Adjustable Tile Handling System

- Compatible with various tile sizes and thicknesses.

- Customizable flipping mechanisms for different tile materials.

3. Advanced Automation and Precision Control

- Sensor-based technology ensures accurate flipping and alignment.

- Integrated Programmable Logic Controller (PLC) for seamless automation.

4. High-Speed and Efficient Performance

- Matches the kiln’s output speed to avoid production slowdowns.

- Handles multiple tiles simultaneously for increased efficiency.

5. Energy-Efficient Design

- Equipped with low-power motors to optimize energy consumption.

- Efficient hydraulic systems minimize operational costs.

6. Safety and Tile Protection

- Soft-touch gripping technology prevents cracks and chips.

- Emergency stop features and overload protection for operator safety.

7. Easy Maintenance and Operation

- Modular design allows quick part replacements and servicing.

- User-friendly control panel ensures simple operation and troubleshooting.

Future Trends in Ceramic Tile Manufacturing

The ceramic tile industry continues to evolve, with new trends shaping production efficiency and quality:

1. Smart Factory Integration

- Use of IoT and AI for real-time monitoring and predictive maintenance.

- Advanced data analytics to optimize tile production.

2. Sustainable Manufacturing

- Adoption of energy-efficient, eco-friendly machinery.

- Reduction in material waste and carbon footprint.

3. High-Speed and Large-Format Tile Handling

- Machines designed for larger tile formats and higher production demands.

- Advanced flipping mechanisms for complex tile designs.

To summarize:

The Kiln Exit Turnover Machine is an essential automation tool for ceramic tile manufacturers, ensuring efficient tile flipping, cooling, and alignment at the kiln exit. Aexea International offers state-of-the-art machinery, helping manufacturers improve efficiency, reduce tile breakage, and enhance product quality.

By investing in a high-quality kiln exit turnover machine, ceramic tile manufacturers can achieve higher productivity, lower operational costs, and superior product consistency, maintaining a competitive edge in the global market.